Past work

The most recently funded project in the ARL repertoire is the texturing of Bi-2212. In 2008 is was hypothesized by ARL students that the high temperature superconductor could be oriented so that superconducting planes in the material could be aligned. Two methods were proven sucessful: magnetic alignment and mechanical alignment. Initial results showed that mechanical texturing proved simpler and had higher texturing.

Current Work

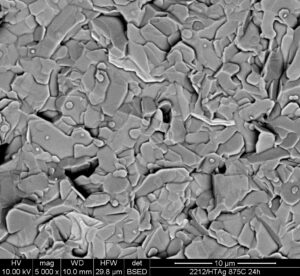

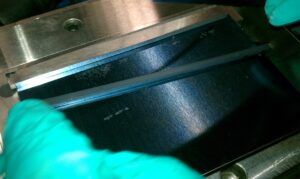

The performance and cost of Bi-2212/Ag wire is limited by the large fraction of Ag matrix (~3:1) that is required in the oxide-powder-in-tube fabrication process. An alternative fabrication process is being developed in which fine-powder Bi-2212 is uniaxially compressed to form bars with a thin Ag foil sheath. The fine powder naturally textures (aligns the a-b planes perpendicular to the direction of compaction) with texture >80% using 200 MPa compression. A billet is formed by stacking trapezoidal-cross-section bars in a symmetric 8-12-16 pattern around an Ag rod and enclosed in an Ag-wall extrusion can. The billet is extruded and drawn to fine wire.

to read more…

Development of multi-filament textured-powder Bi-2212/Ag wire with enhanced LAR, Proc. Applied Superconduct. Conf., Tallahassee, Oct. 24 – Nov. 7, 2020.