Benefits

- Center tube provides much stress management by using its elasticity as each wire is compressed to immobilize them under Lorentz forces

- The perforated tube allows easy access to the cable and path for liquid He

- Alleviates problems of degradation that occur in ‘cable-of-ropes’ CIC method

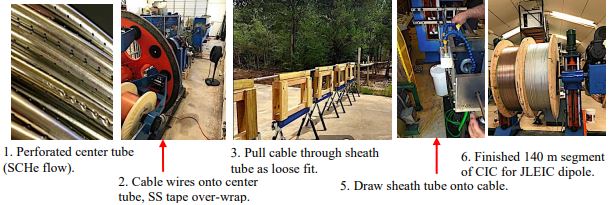

Process of making SuperCIC cable at ATC’s facility (Capable of 140 m lengths)

Currently long lengths of NbTi have been fabricated and Nb3Sn is being developed for use in the outsert winding of a hybrid dipole magnet between it and REBCO. These will be manufactured as outsert and insert windings separately since Nb3Sn requires a heat treatment.